Check & Repair Pro is an innovative solution within MultiPress that automatically checks and corrects PDF files via Smart Onboarding from the very first administrative step, such as during quotation, order creation or file upload. This way, issues like missing bleed, low resolution, incorrect colour settings or wrong dimensions are immediately detected, even before the prepress department gets involved. With Check & Repair Pro in MultiPress, the team has a powerful tool to immediately check incoming PDF files, quickly, visually, and comprehensibly.

MultiPress Check & Repair Pro: seamless PDF processing in MultiPress

Smart Onboarding stands for the structured and automated checking of incoming PDFs. Thanks to the updated Check & Repair Pro module, the order manager receives a clear status overview upon receipt of the file, without having to wait for prepress.

With MultiPress Check & Repair Pro, every PDF file is checked against the order information. Technical elements such as image resolution, bleed, colour profiles and page size are assessed based on the latest ISO and GWG standards. Thanks to the integrated ‘Intent Preflight’ and ‘Processing Steps’, users can apply specific production criteria to inspect PDF files more accurately and in greater detail.

In other words, MultiPress Check & Repair Pro understands the production context of each file. With Intent Preflight, only the relevant parameters are checked. A billboard, for instance, is checked for resolution, dimensions and bleed, while a brochure is assessed using entirely different criteria. More targeted, smarter, and always aligned with the right quality standards.

Any deviations are flagged immediately within MultiPress, via a clear and intuitive control panel. The order manager has access to a smart toolbox that helps process issues and comments efficiently. Check & Repair Pro goes well beyond the classic Check & Repair in MultiPress. It not only detects errors, but also enables guided corrections with clear recommendations. This means administrative staff, regardless of prepress experience, can confidently perform professional PDF checks. As a result, files are fully ready for production without extra steps or delays.

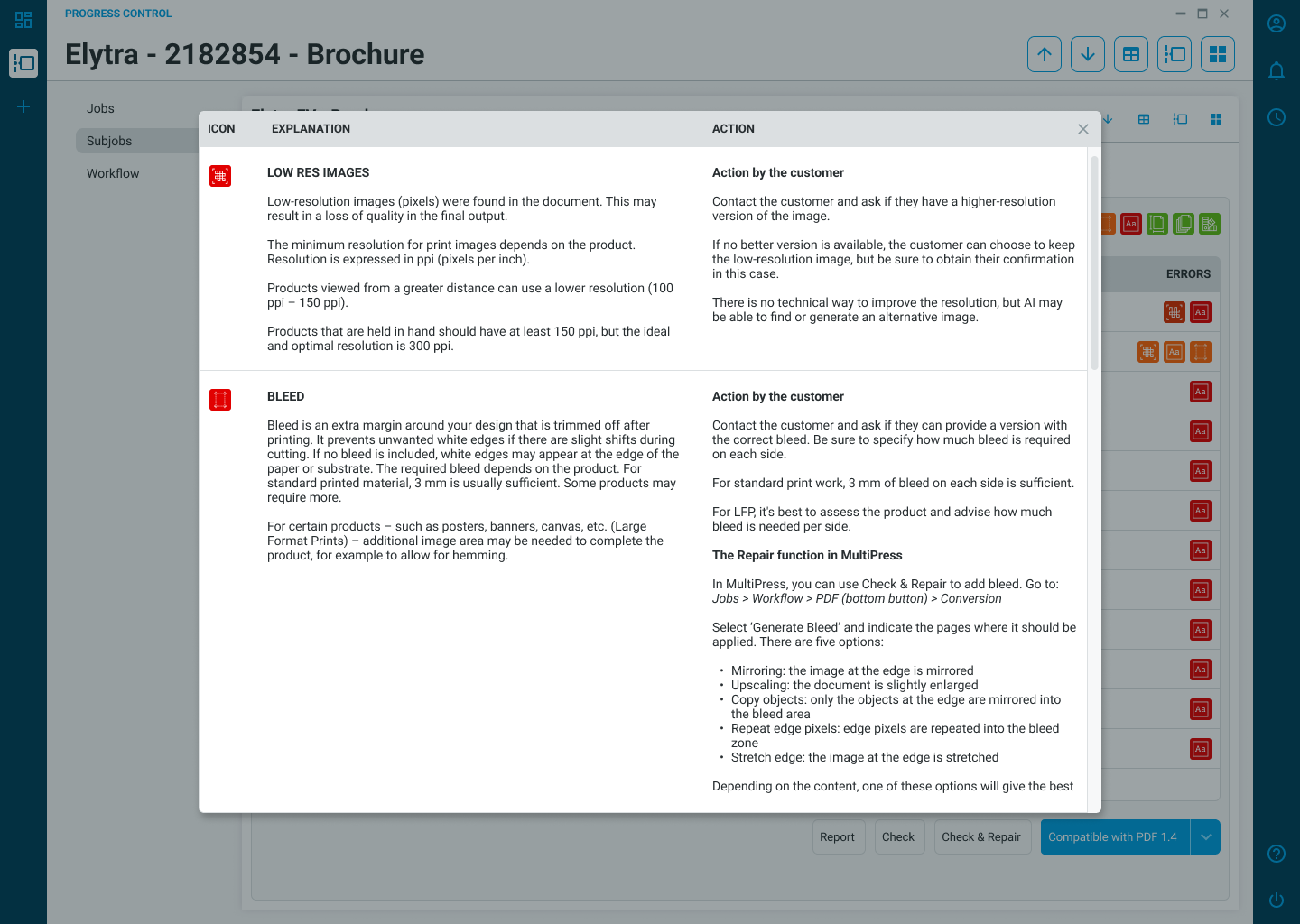

Six smart icons for complete control

When onboarding a PDF file, it is essential to quickly and accurately assess whether the file is suitable for production. With Check & Repair Pro, we have simplified this process by introducing six recognisable icons. These icons provide immediate visual feedback on the technical state of the file and are directly linked to the product information already present in the MultiPress order.

Thanks to these icons, order managers and other users can immediately assess whether a file meets the requirements of the final product. Each icon represents a common issue that may occur during the intake of PDFs.

These are the six checks that are performed by default:

- Low-resolution images: When an image in the PDF has a resolution that is too low for a high-quality result, this is clearly reported. The report also specifies exactly where this image is located, allowing the customer to take prompt action.

- Incorrect format (trimbox): The file dimensions are checked against the product definition in MultiPress. If the format does not match what is expected, this is immediately indicated visually.

- Font issues: Font errors are an absolute 'NO GO'. Think of missing fonts, incorrectly embedded fonts, or other typographic errors that could jeopardise the reproducibility of the file.

- Insufficient bleed: Sufficient bleed is often essential for proper processing. This check is based on the selected production method and product type, ensuring that cutting margins and finishing processes go smoothly.

- Incorrect number of pages: The number of pages in the submitted file is compared with the information in the order. Too many or too few pages may indicate an error in submission or interpretation of the assignment.

- Colour issues: Finally, it is checked whether the colour usage matches the expectations from the order. Think of spot colours being used where CMYK is required, or colour profiles that are not compatible with the set production process.

Does the PDF standard you use really make that much of a difference?

Although PDF/X-1a was the standard for many years, this specification no longer meets the demands of modern production processes. Transparency is forcibly flattened, layers are lost, colour management is limited, and additional workflow steps are needed to avoid problems. That means more manual work, a greater risk of errors, and less visual control. Still, many companies continue to rely on this outdated standard, often out of habit, or because they are not fully aware of the benefits offered by newer alternatives.

When building our smart profiles, we deliberately choose the modern PDF/X-4 standard as a starting point. This standard is perfectly aligned with the capabilities of contemporary workflows, including the Adobe PDF Print Engine (APPE), which is now the norm in most professional production environments.

Thanks to this approach, users benefit from several key advantages:

- Full support for transparency, layers, and colour management: Unlike older specifications, modern PDF/X-4 files can be processed without flattening, preserving the original design intent entirely.

- Suitable for digital presses with a wide colour gamut: Think of devices that support not only CMYK but also orange, green, or violet. PDF/X-4 makes it possible to fully utilise these additional colours in the submitted file.

- More flexibility, fewer limitations: Users are no longer constrained by the strict limitations of PDF/X-1a. This means fewer adjustments, less information loss, and therefore higher visual quality.

- No need for flattening or cumbersome conversions: Flattening transparency can result in errors, visual artefacts, or quality degradation. Thanks to PDF/X-4, this is a thing of the past. The file can be processed directly and flawlessly by modern RIP software.

The updated Check & Repair Pro module in MultiPress is therefore not only user-friendly but also technically fully aligned with the current standards in the graphic industry.

MultiPress Check & Repair Pro wins EDP Award 2025

Read more

Why Check & Repair Pro (Smart Onboarding) is a game changer

Check & Repair Pro is a smart extension of MultiPress that makes processing PDF files easier, faster, and more reliable. Thanks to automatic checks, visual alerts, and integration with modern standards, you gain control over one of the most crucial steps in your production process: onboarding the submitted file.

The benefits at a glance:

- Checks from the start: PDF files are automatically checked upon upload, during the quote process or when creating the order. This way, you catch errors before prepress is involved;

- Six check icons: recognisable visual alerts instantly show whether a file is suitable for production and where any issues are located;

- Based on product information: the check adapts to the product type in MultiPress, ensuring you always receive relevant feedback for the kind of print work, such as a brochure or billboard;

- Not just detection, also correction: deviations can be corrected automatically, with concrete recommendations and without extra intervention;

- Fully aligned with modern PDF standards: with PDF/X-4, transparency, layers, and wide colour support are perfectly handled. Your files are ready for the latest digital presses and workflows;

- User-friendly and visual: all information is clearly presented in the MultiPress control panel. Reports can also be customised to match your corporate identity;

- Fewer errors, faster production: avoid wasting time, eliminate correction cycles, and equip your team with tools to perform professional quality control independently;

In short: with Check & Repair Pro, you streamline the entire onboarding process of PDF files. You work faster, smarter, and with more confidence towards production.

Want to know more? Contact Dataline and discover how you can make a difference with Smart Onboarding in MultiPress.

Schedule a meeting with our PDF experts now!